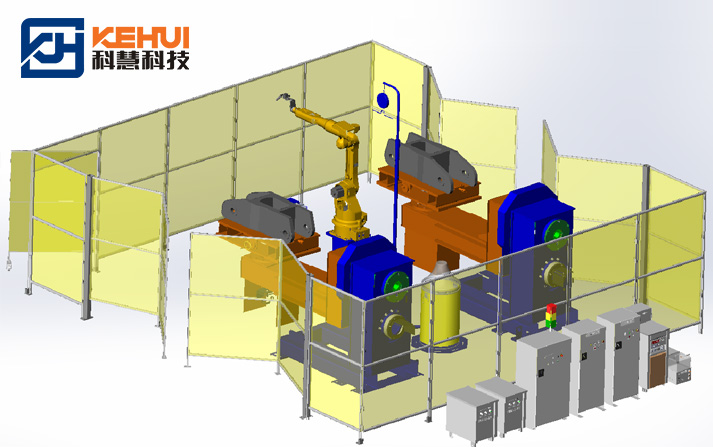

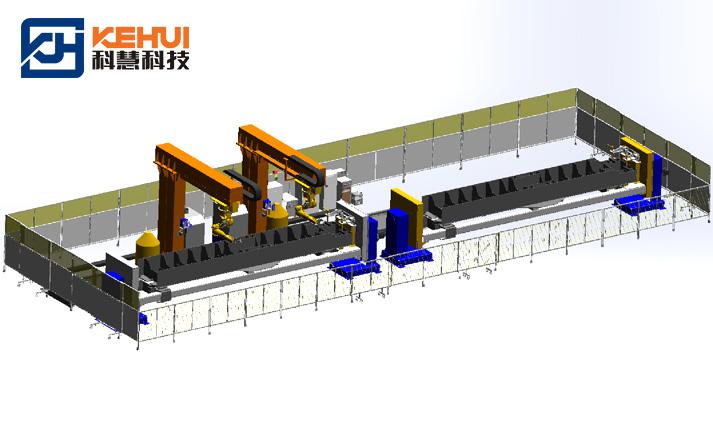

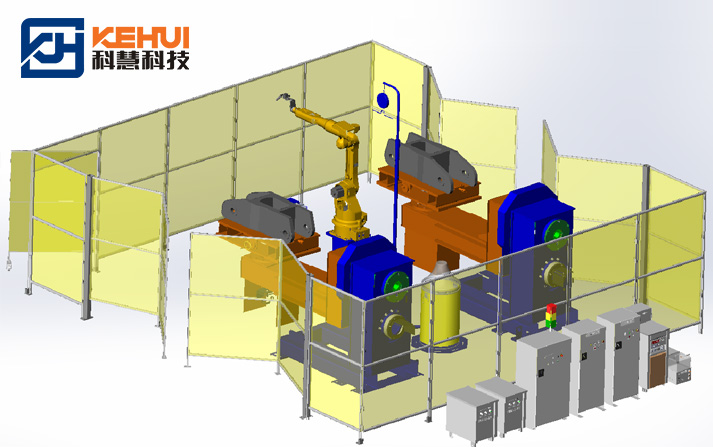

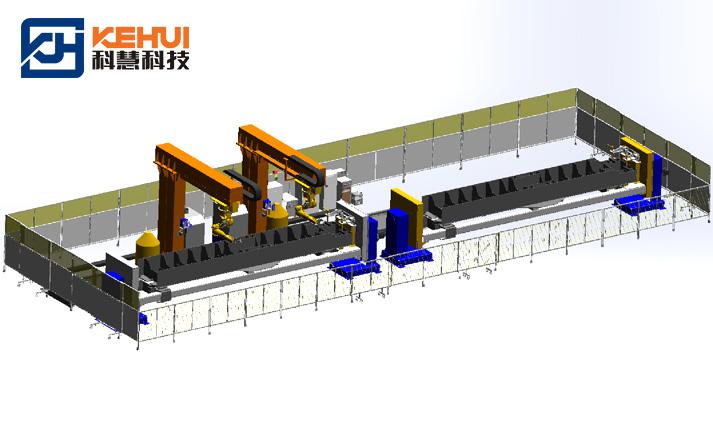

1. Robot hoisting and moving device expands the effective welding radius of the robot.

Through hoisting and moving slides, the welding robot can realize that the robot system can operate at multiple stations, which can ensure that the weld is always in good condition and is conducive to weld formation.

2. The welding process is carried out in sequence according to the pattern, with high consistency

The application of digital control power supply in automatic welding equipment makes the output of welding power supply more stable and more accurate. Through a lot of practical accumulation and summary of various welding parameters, the heat input of the welding connection area is accurately controlled to ensure that the quality of the weld meets the product specifications and remains stable.

3. The station fixture can achieve fast switching and strong flexibility

The fixture adopts an integral or combined structure, which is easy to disassemble and assemble. At the same time, the welding program can be quickly switched on the overall control touch screen of the whole line, thereby realizing the fast switching of the production of different product workpieces. Shorten the preparation cycle for product modification (only need to modify the software and necessary fixtures, etc.), reduce the corresponding equipment investment.

4. Improve the processing environment, reduce labor intensity, and improve welding quality and assembly level.

Through the reasonable application of automatic welding technology, the efficiency of welding work can be effectively improved while improving the labor environment, getting rid of the influence of welder level, the welded joint morphology is regular and flat, and can be used directly after welding without further processing, shortening the process.

5. The welding operation speed can be adjusted, with good structural rigidity.

High-quality equipment configuration and intelligent integrated control system effectively guarantee fast welding, taking advantage of the fast servo rotation speed, which is conducive to cross welding and reducing the welding deformation of the workpiece.